If you’re wondering how to fix a bent stainless steel propeller, it’s important first to understand what a bent prop is.

A bent propeller occurs when one or more blades are deformed due to hitting rocks, debris, shallow water, or accidental impacts.

Even a small bend can cause vibrations, reduce speed, lower fuel efficiency, and strain your engine.

To fix a bent stainless steel propeller, you need to remove it from the boat and carefully inspect the damage.

Unlike aluminum props, stainless steel requires specialized tools, such as a hydraulic prop press or professional repair services, to realign the blades.

Do not attempt hammering, as this can worsen the damage or cause cracks. In cases of severe bends, professional blade replacement may be necessary.

In this guide, we’ll cover everything from identifying bent blades and DIY maintenance tips to professional propeller restoration, costs, and preventative measures. Therefore, let’s get started!

Signs Your Stainless Steel Propeller Is Bent

Here’s how to identify a bent propeller and inspect it properly.

1. Vibrations While Driving

A bent propeller disrupts the balance of your boat’s propulsion system, which causes vibration.

These vibrations can be felt throughout the boat, especially at higher speeds, and may cause discomfort for passengers.

2. Excessive Fuel Consumption

A bent propeller forces the engine to work harder to maintain speed and leads to increased fuel consumption.

This inefficiency arises because the damaged propeller cannot transfer engine power to the water as effectively. It causes the engine to over-rev and consume more fuel.

3. Reduced Speed or Poor Acceleration

Damage to the propeller blades, such as bending or missing material, can impede the propeller’s ability to push water effectively.

This results in decreased top speed, sluggish acceleration, and difficulty reaching plane, as the engine struggles to achieve optimal RPMs.

4. Visible Blade Damage or Deformation

Physical inspection of the propeller may reveal visible signs of damage, such as bent blades, dings, chips, or cracks.

Even minor deformations can affect the propeller’s balance and performance.

How to Inspect a Bent Stainless Steel Propeller

Follow these steps to ensure a comprehensive evaluation.

1. Visual Inspection

Examine each blade for visible damage such as cracks, chips, or corrosion.

Use a straight edge to check for any bends or warps by comparing the alignment of each blade.

Run your fingers lightly over the blade surfaces to feel for any irregularities or rough spots.

2. Blade Symmetry Check

With a tape measure, compare the length of each blade from the hub to the tip.

Ensure all blades are aligned and not twisted, as this can affect performance. Look at the blades from different angles to ensure they are symmetrical.

3. Spin Test

Mount the propeller securely on the boat or a stand. Manually rotate the propeller and observe its movement.

Watch for any wobbling or uneven rotation, which can indicate a bent shaft or an imbalanced propeller.

Can You Fix a Bent Stainless Steel Propeller Yourself?

Stainless steel is a rigid material that requires specialized tools and expertise to repair effectively.

The material’s hardness necessitates precise techniques, such as TIG welding and controlled heating, to avoid compromising the propeller’s integrity.

Without the proper equipment and knowledge, DIY repairs can lead to further damage or failure.

DIY Risks vs. Professional Repair Shops

While DIY repairs may seem cost-effective, they carry several risks,

- Inadequate Repair

- Safety Hazards

- Increased Costs

Professional repair shops have the expertise and equipment to restore propellers to their original specifications, ensuring safety and performance.

Temporary DIY Fixes

For minor damage, such as small chips or burrs, temporary fixes may be attempted. You can try carefully sanding the damaged area to smooth out minor imperfections.

Or, using marine-grade filler to fill small chips can restore surface smoothness. These methods are only suitable for minor cosmetic issues and do not address structural damage.

Emphasize Safety Precautions

If attempting any DIY repairs:

- Wear Safety Gear: Always wear gloves, eye protection, and other appropriate safety gear.

- Work in a Safe Environment: Perform repairs in a well-ventilated area, away from flammable materials.

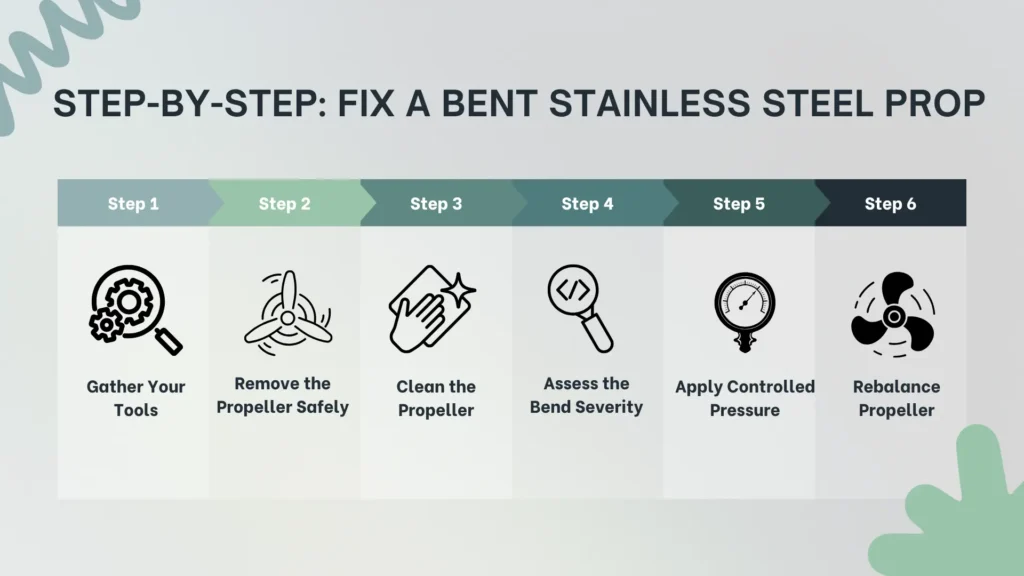

How to Fix a Bent Stainless Steel Propeller: Step-by-Step

Follow these detailed steps to safely address minor bends.

Step 1: Gather Your Tools

Before starting, ensure you have the right tools:

- Hammer (steel, brass, or rawhide): For controlled bending.

- Hardwood block: Provides a stable surface for support.

- Protective gloves and eye protection: Critical for safety.

- Measuring tape or straightedge: To check blade alignment.

- Crescent wrench or vice (optional): Assists in precise adjustments.

Step 2: Remove the Propeller Safely

At first, turn off the engine and ensure the boat is secured. Then, carefully detach the propeller from the shaft using the correct tools.

Step 3: Clean the Propeller

Remove marine growth, dirt, and debris using a soft brush and water.

Cleaning the propeller ensures that damage is visible and prevents further scratching during repair.

Step 4: Assess the Bend Severity

Examine each blade for visible bends, cracks, chips, or twists.

Use a measuring tape or straightedge to compare blade lengths and alignment. Determine if the bend is minor or severe.

Step 5: Apply Controlled Pressure

For minor bends, gently heat the affected area using a propane torch to make the metal slightly more malleable. Do not overheat, as stainless steel can weaken.

Place the blade over the hardwood block and use the hammer to apply controlled taps, gradually straightening the blade.

If needed, use a vice or crescent wrench to apply leverage carefully.

Step 6: Smooth Edges

Use a file or grinder to remove any burrs or sharp edges created during the bending process.

Smooth edges prevent water drag and protect against injury.

Step 7: Rebalance the Propeller

After repairs, manually spin the propeller on a flat surface or shaft. Then, observe for any wobble or uneven rotation.

Remove small amounts of material from heavier areas if needed to achieve balance.

Step 8: Reinstall and Test

Reattach the propeller securely to the shaft. After that, test at low speeds first, checking for vibrations and smooth operation.

If vibration persists, reassess or consider professional repair.

Professional Repair vs. Buying a New Propeller: Making the Right Choice

Understanding the costs, benefits, and circumstances surrounding each option can help you make an informed decision.

Average Repair Costs

Repairing a stainless steel propeller generally ranges from $200 to $400, based on the extent of the damage and the repair shop’s rates.

Replacement Costs

New stainless steel propellers are priced between $400 – $700, with high-performance models exceeding this range.

If replacement is the better choice, the VIF Jason Marine 10.5″ x 15″ Stainless Steel Propeller is the best choice.

Designed for Mercury outboard engines ranging from 25 – 70 HP, this propeller is crafted from durable duplex stainless steel. It also offers enhanced performance and longevity.

How to Prevent a Bent Stainless Steel Propeller?

Here are effective strategies to prevent bending your stainless steel propeller.

1. Avoid Shallow or Rocky Waters

Navigating in shallow or rocky areas increases the risk of propeller strikes against submerged obstacles.

To minimize this risk, always consult detailed charts to identify potential hazards in your route.

Reduce speed when operating in unfamiliar or shallow waters to allow for a quick response to unexpected obstacles.

Raising the engine slightly can help avoid contact with the bottom in shallow areas.

2. Install a Propeller Guard

A propeller guard can provide an additional layer of protection by reducing the possibility of direct contact with underwater objects. However, consider the following:

They are particularly beneficial in low-speed, high-risk environments such as marinas or areas with heavy vegetation.

3. Conduct Regular Maintenance Checks

Regularly check for cracks, chips, or bends in the propeller blades.

Have your propeller professionally serviced periodically to maintain its integrity and performance.

4. Proper Storage

When not in use, ensure your propeller is stored and transported correctly to prevent accidental damage.

Cover the propeller during storage to shield it from debris and environmental factors.

FAQs

1. Can you straighten a bent stainless steel propeller at home?

Yes, you can straighten minor bends at home, but stainless steel is very rigid and requires specialized tools. Attempting DIY repairs without proper equipment may worsen the damage. For best results, consider using a hydraulic prop press or a professional repair service.

2. How do I know if my stainless steel propeller is damaged?

Common signs include:

- Vibrations while driving

- Reduced speed or poor acceleration

- Excessive fuel consumption

- Visible blade bends, chips, or cracks

3. Is it worth repairing a bent stainless steel propeller?

Yes, if the bend is minor and the blades are not cracked or severely warped, then it’s worth repairing. Professional repairs can restore performance at a fraction of the cost of a new propeller. For severe damage or structural issues, replacement is usually the smarter option.

4. Can a bent propeller damage my boat’s engine?

Yes, a bent propeller can damage your boat’s engine. A bent propeller creates vibration and imbalance, which can strain the engine, transmission, and drivetrain. Ignoring a bent prop can lead to costly mechanical problems over time.

5. How long does it take to fix a stainless steel propeller?

Minor repairs by a professional can often be completed within a few hours to a day, depending on the severity. Severe damage or replacement may take longer, particularly if ordering a new propeller.

Conclusion

Ignoring a bent stainless steel propeller can lead to serious problems, including increased fuel consumption, engine strain, and even potential engine failure.

Even minor blade damage can reduce efficiency significantly, while vibrations from an imbalanced propeller can prematurely wear bearings, seals, and other critical engine components.

For minor bends, professional repair services can often restore the propeller’s performance at a fraction of the cost of a new one.

However, severe damage may require full replacement to ensure optimal efficiency and safety.

Regular maintenance and addressing propeller issues promptly are essential steps in preserving the longevity of your propeller.